Oil sludge treatment system

Turn Oil Sludge Waste into Profitable Resources

Outstanding Oil Sludge Treatment Technology

Transforming Hazardous Waste into Valuable Resources

Sludge Properties:

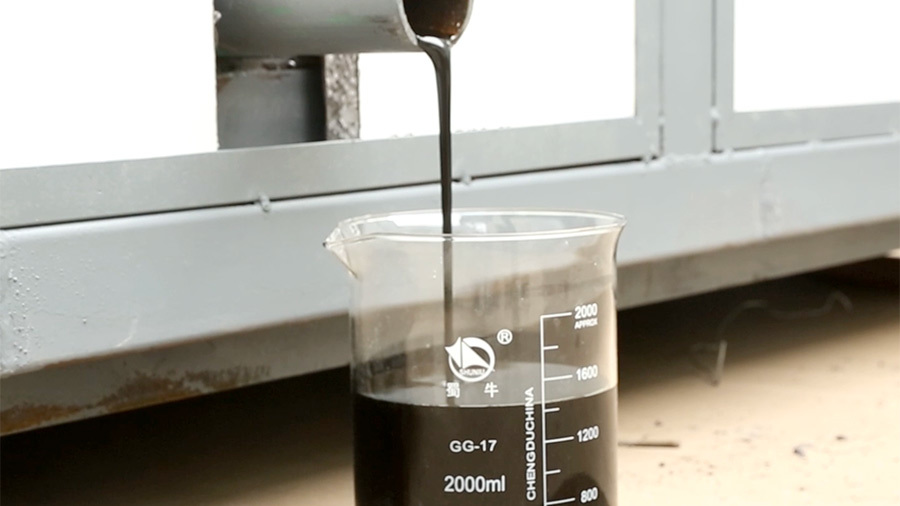

Oil sludge is a byproduct generated during petroleum extraction, transportation, processing, and storage. This encompasses various forms, including oil sludge, oil-contaminated soil, and carbon black. Oil sludge consists of numerous hazardous constituents, including carcinogenic hydrocarbons (polycyclic aromatic hydrocarbons and benzene derivatives), heavy metals (lead, mercury, and arsenic), and mutagenic compounds. The presence of oil sludge poses a significant threat to environmental integrity and public health; consequently, governments have classified it as a hazardous waste material.

Solution:

Traditional Treatment Methods:

Methods such as landfill disposal and incineration carry the potential for regulatory penalties and long-term environmental pollution.

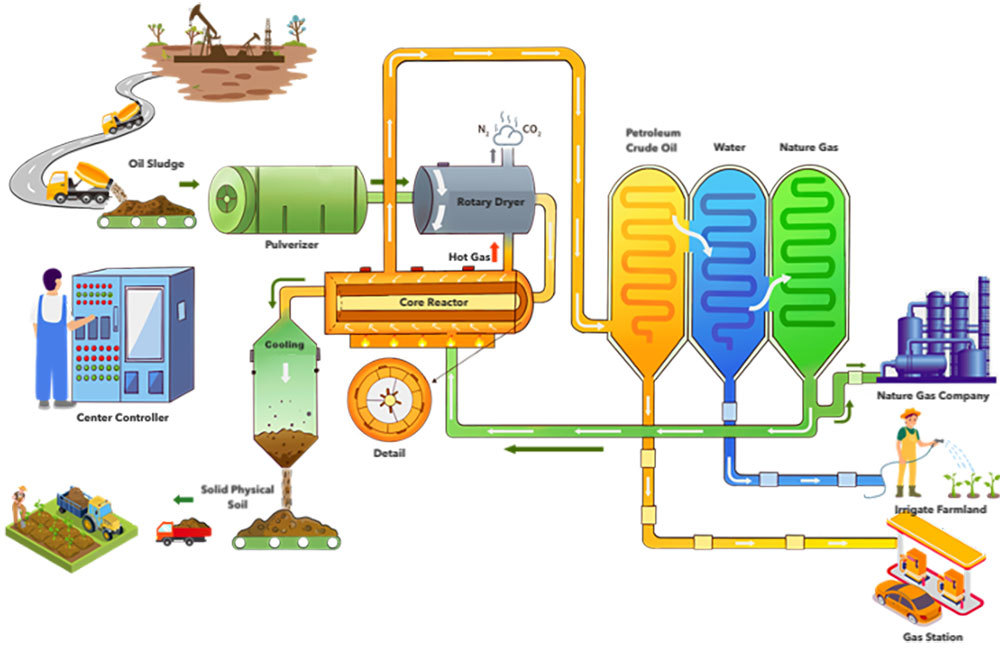

Employing BIRC Technology for Processing:

The sludge is effectively transformed into oil, water, solids, and combustible gas, which can be reutilized as energy. Relevant departments have conducted tests on the solid emissions, and all indicators comply with national emission standards.

Results from third-party testing on the certification of BIRC pyrolysis technology are under national standards:

Outcome Products | BIRC Achievements | Test Results | National Standards |

Oil | Return rate > 99.94% | |

|

Water | Return rate > 99.7% | Petroleum substances: 7.05mg/L COD 26 mg/L BOD 5.1mg/L | Petroleum substances: 20mg/L COD 500mg/L BOD 300mg/L |

Solid Matters | Return rate 100% | Oil content: 59mg/kg Mercury: 0.12mg/kg Lead: 29.20mg/kg | Oil content: 3000mg/kg Mercury: <15 mg/kg Lead: <1000mg/kg |

Combustible Gas | Return rate > 99% |

|

|

Technical Highlights:

- Productivity may be collected across various systems using precise and intelligent temperature control.

- The oil return rate is impressive at 99.94%, facilitating the direct sale of oil products to external markets.

- The water treatment process has effectively reduced the chemical oxygen demand (COD) level to 26 mg/L, exceeding the national standard of 500 mg/L. The treated water is deemed appropriate for recycling as industrial water.

- The solid material from pyrolysis may be repurposed as soil for reforestation projects and as supplementary materials in construction activities.

- The combustible gas generated through pyrolysis is appropriate for on-site applications or may be commercialized externally

- This technology effectively converts waste into valuable resources by guaranteeing sustained production within oil fields over prolonged durations, ensuring stable operational procedures, and meeting emissions that adhere to national emission standards.

At SunGene, we are convinced that, considering the increasing demand for energy and the nation's expanding environmental protection requirements, implementing BIRC technology will herald a significant transformation in the treatment of oil sludge.

Category: