Coal treatment system

Transforming Coal Efficiency for Maximum Energy Output

Enhance the efficiency of coal utilization and achieve clean energy

Maximize energy output through BIRC's clean coal technology.

Global Coal Situation

Coal continues to serve as the fundamental basis for global power generation, with various types of coal characterized by distinct carbon contents and utilization rates:

Coal Type | Carbon Content | Global use | Main Applications |

Anthracite | 86%–97% | 5%–7% | Professional industrial use |

Bituminous Coal | 45%–86% | 50%–55% | Electricity, steel production |

Sub-bituminous Coal | 35%–45% | 15%–20% | Power Generation |

Lignite | 25%–35% | ~24% | Electricity, heating |

Although subbituminous coal and lignite predominantly drive global power generation owing to their substantial reserves, their low carbon content and high levels of impurities- such as moisture, volatile matter, and ash- restrict energy efficiency and profitability.

Properties of Substandard Coal:

Low Calorific Value:

A reduced carbon content directly impacts heat generation efficiency.

High Operating Costs:

Excess moisture and impurities may elevate shipping and processing expenditures.

Environmental Concerns:

Combustion processes contribute to increased emissions and waste generation.

BIRC technology represents the future of clean coal utilization.

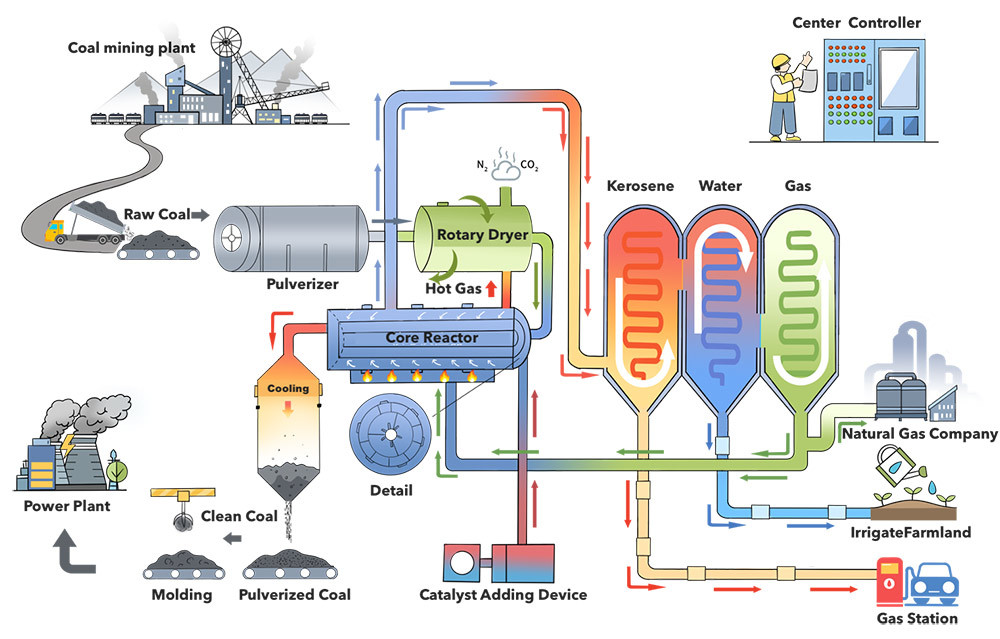

The built-in indirect external heating online rotary catalytic pyrolysis (BIRC) process can extract all available energy from raw coal, enhance its quality, increase the efficiency of coal utilization, and generate maximum economic benefits.

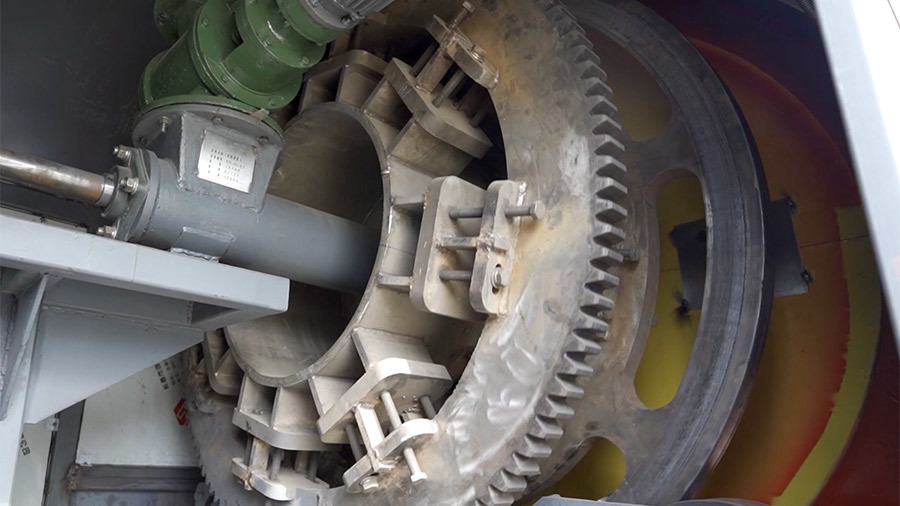

How BIRC Pyrolysis Technology Works?

Pyrolysis Process:

Under the specific procedural conditions established by BIRC, organic matter is heated to a predetermined temperature to promote its decomposition.

Carbon Rich:

This process accumulates and stabilizes carbon, thereby resulting in an enhancement of carbon density and calorific value.

Streamlined Production:

An enhanced energy conversion rate output is achieved by optimizing systems, integration, and programming.

Energy Saving and Environmental Protection:

This approach serves to minimize pollutant emissions while enhancing environmental quality.

Why choose BIRC?

- International Certification: ISO Certified

- The system has successfully undergone a technical evaluation conducted by the People's Republic of China Energy Administration.

- Based on statistical data obtained from testing, power plants that implement BIRC technology can reduce their raw coal consumption by approximately 10% annually while maintaining equivalent thermal output.

Simultaneously, BIRC enhances quality and efficiency, mitigates carbon dioxide emissions, decreases production costs, and maximizes profits. The technology and equipment provided by BIRC effectively reduce carbon emissions, ensure safety and reliability, achieve high efficiency and energy conservation, and operate intelligently.

Category: